Trident CNC Plasma Table for Sale

The Trident CNC Plasma Table embodies strength, versatility, and quality, serving as the inspiration behind our premier entry-level CNC plasma cutting solution. Designed with a threefold purpose—sparking creativity, promoting learning, and delivering long-lasting performance—this table combines cost-effectiveness with robust functionality.

This single plasma system ensures hassle-free operation, featuring EZnc®—the easiest Plasma CNC interface on the market. With its intuitive design, even beginners can quickly learn and operate the system, reducing setup time and maximizing productivity. Combined with high-quality components built to endure rigorous use, the Trident is the ideal choice for educational institutions and manufacturing companies seeking an economical entry point with rapid ROI. Whether you aim to increase throughput or reduce production costs, this versatile machine meets the challenge.

Capable of speeds up to 1000 inches per minute, the Trident operates on integrated linear bearings and boasts 400 oz-in stepper motors, delivering smooth, precise motion via 17mm helical rack in the X and Y axes. A lead screw-driven Z-axis lifter ensures reliable, accurate vertical motion.

Equipped with Hypertherm® Powermax® plasma torches and power supplies, the Trident eliminates the need for specialty gases, cutting through materials up to 1 inch thick with ease.

Built by the Best in the Industry

The Trident CNC Plasma Table is designed and built by the leading experts in CNC plasma cutting technology. Our team’s deep industry knowledge and commitment to quality ensure that every Trident machine delivers precision, durability, and ease of use. Whether you’re just getting started or looking to optimize production, trust the Trident—engineered for excellence.

Key Features:

– Designed and built by the best in the industry for unmatched quality and reliability.

– EZnc® – the easiest Plasma CNC interface on the market for simple, user-friendly operation.

– Entry-level production machine designed for learning and industrial applications.

– Cost-effective solution with a fast return on investment.

– Reliable motion control with precision-engineered components.

– High-speed operation for efficient workflow.

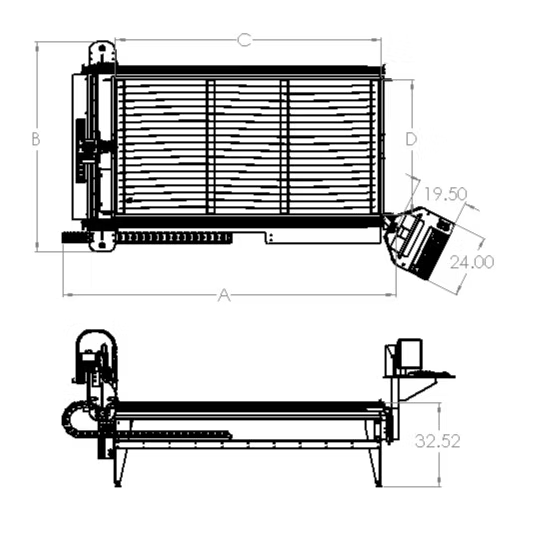

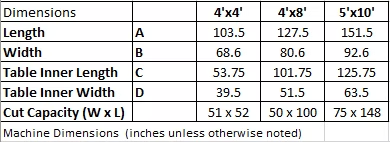

Specifications

- Unitized CNC Table:

– Provides “unload, level, plug in and cut” installation for quick setup

– Easily movable on-site for maximum flexibility

– Customized user interface, initial height sense, and arc voltage height control

– Powered by open-source LinuxCNC real-time motion controller

– Fanless embedded industrial PC for reliable operation

– Integrated plasma control and arc voltage height control

– Available in 4’x4′, 4’x8′, or 5’x10′ table sizes

Torches:

– Compatible with Hypertherm Powermax 45XP through Powermax 125

– Pierces up to 1” material thickness

– Severs up to 2.5” thick material

Drives:

– Ethernet-linked drive and I/O box for smooth communication

– 400 oz-in stepper motors on X, Y, and VY axes for precise motion

– 17mm helical rack for smooth, extended-life motion

Lifter:

– 400 oz-in motor with lead screw motion for precision height control

– Integrated contact sense and magnetic torch breakaway sensor