Our American Built Tables

The Best CNC Plasma Table, Built by Experts The Trident CNC Plasma Table is the best entry-level plasma CNC on the market, delivering unmatched precision, reliability, and ease of use. Featuring EZnc®—the simplest CNC interface available, Hypertherm® Powermax® torches, and cutting speeds up to 1000 inches per minute, Trident is built for performance. Designed and manufactured by industry leaders, it offers a fast ROI, seamless operation, and industrial-grade durability. Invest in the best—Trident CNC.

The Best Heavy-Duty CNC Plasma Table – Built for Professionals The Razor CNC Plasma Table is the ultimate heavy-duty cutting solution for metal fabrication shops and technical schools. With 1200 IPM cutting speeds, 620 oz-in servo motors, and an adjustable water table, Razor delivers precision, power, and efficiency. Featuring EZnc®—the easiest CNC interface available, it ensures seamless operation. Built for those who demand the best, Razor is the industry’s top choice for speed, accuracy, and reliability.

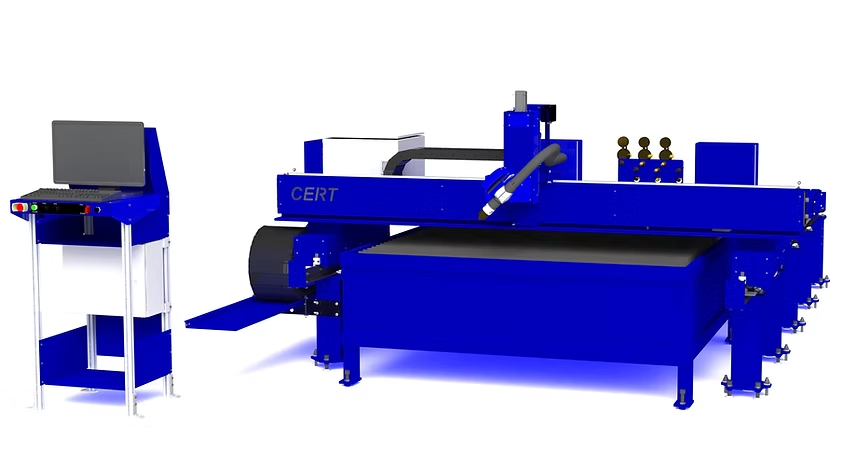

The Best Large-Format CNC Plasma Table – Built for Industrial Cutting The Tizona CNC Plasma Table is the ultimate large-format CNC cutting solution, handling sheets up to 10 feet wide and over 100 feet long with 1200 IPM cutting speeds and 620 oz-in servo motors. Featuring EZnc®—the easiest CNC interface available, and a fully adjustable water table, it delivers unmatched scalability, precision, and efficiency. Built for industrial manufacturers, Tizona is the best choice for large-scale, high-performance plasma cutting.

The Best CNC Plasma Table Ever Built – Period. The Lobera CNC Plasma Table is the Cadillac of CNC plasma systems, offering unrivaled power, size, and precision. With sizes from 4 feet to 16 feet wide and up to 200 feet long, 3000 IPM speeds, and 1000-watt servo motors, Lobera is built for elite manufacturers. Featuring Hypertherm Edge Connect® CNC controls and XPR torches up to 460 amps, it pierces over 2” and severs over 3” with ease. When only the best will do, choose Lobera For all of your industrial cutting needs.