LOBERA

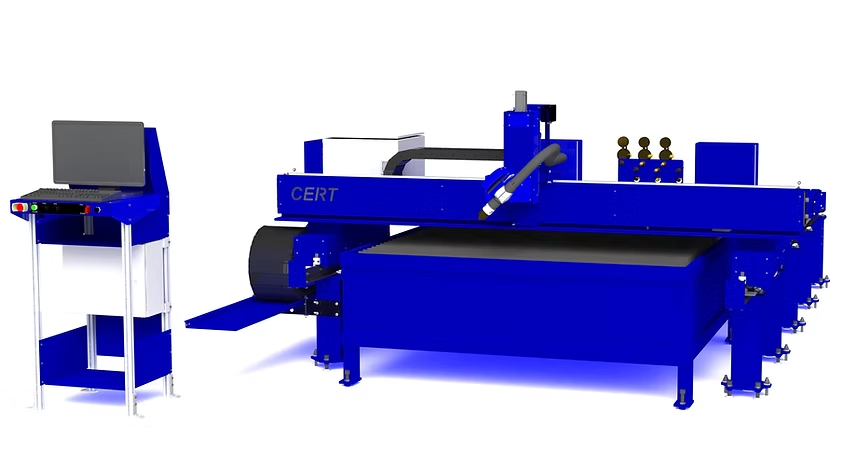

Lobera CNC Plasma Table – The Pinnacle of Industrial CNC Plasma

The Lobera CNC Plasma Table is the Cadillac of CNC plasma systems—a masterpiece of engineering designed for elite manufacturers who demand the absolute best. Built for large-scale production, Lobera offers widths from 4 feet to 16 feet and lengths up to 200 feet, making it the most powerful and versatile CNC plasma table in its class.

With blazing fast speeds of 3000 inches per minute (IPM), 1000-watt servo motors, and the Hypertherm Edge Connect® CNC system, the Lobera delivers unparalleled precision, speed, and automation. Featuring Hypertherm’s XPR series torches (up to 460 amps), it effortlessly pierces over 2” and severs over 3” of thick material, making it the gold standard for high-performance CNC plasma.

Why Choose Lobera? Because Nothing Else Comes Close.

– The most advanced industrial CNC plasma table—designed for elite manufacturing.

– Unrivaled range – from 4 feet to 16 feet wide and up to 200 feet long.

– Hypertherm Edge Connect® CNC system for the most precise and reliable automation.

– Blazing fast speeds – up to 3000 IPM for maximum efficiency.

– 1000-watt servo motors with EtherCAT-linked drives for smooth, high-power motion control.

– Hypertherm XPR series torches (up to 460 amps) for the thickest industrial materials.

– Pierces over 2” and severs over 3” thick—handling extreme applications with ease.

– Fully adjustable water table for superior fume control and cut quality.

– Aerospace-grade precision with planetary gearboxes and helical rack motion.

– The industry’s smoothest, most intuitive CNC experience with a 22” touchscreen and wireless keyboard.

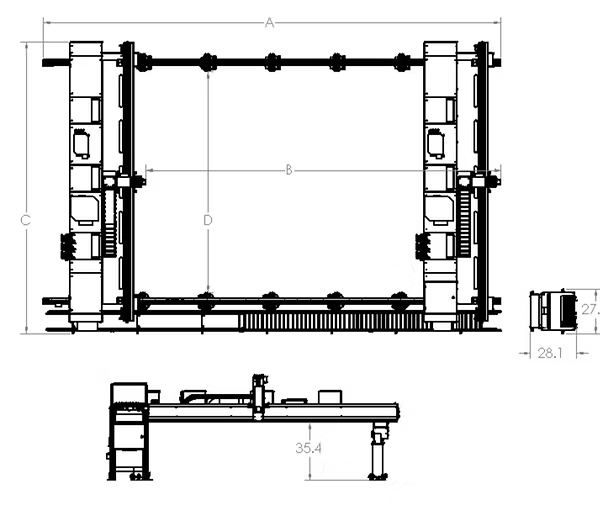

Specifications

Unmatched Engineering

Heavy-Duty Modular CNC Table:

– Scalable sizes – from 4 feet to 16 feet wide and up to 200 feet long for the largest industrial applications.

– 6” H-beam construction with ½” thick bottom anchor plate for rock-solid stability.

– Advanced hydraulic dampened motor transport system for smoother, faster acceleration.

– Extruded aluminum beam for high torsional stiffness—lighter, yet stronger than steel beams.

Motion System – Unstoppable Performance:

– 1000-watt servo motors with EtherCAT-linked drives for precision at high speeds.

– Precision planetary gearboxes on X, Y, and YY axes for aerospace-grade accuracy.

– 24mm M2 helical rack & pinion drive system—the smoothest, most durable motion system available.

Torch & Material Capacity – The Power to Cut Anything:

– Hypertherm XPR series (170-460 amps), MAX Pro 200, and Powermax compatibility for ultimate performance.

– Supports oxyfuel for additional material versatility.

– Over 2” pierce capacity—effortlessly cuts through ultra-thick materials.

– Over 3” sever capacity—for extreme fabrication needs.

Lifter System – Precision at Every Level:

– Plasma (Straight): 400-watt servo motor with ballscrew motion, integrated contact sense, and magnetic torch breakaway for safety.

– Plasma (Bevel): 400-watt servo motor on Z-axis, 100-watt servo motors on A and B axes with ±50-degree bevel range for advanced processing.

– Oxyfuel: 120VAC gear motor with ballscrew motion for heavy-duty plate work.

CNC Control & Automation – Intelligence at Your Fingertips:

– Hypertherm Edge Connect® CNC with a fanless embedded industrial PC for the most reliable, feature-rich operation.

– Massive 22” touchscreen and wireless keyboard for effortless control.

– Seamless integration with Hypertherm’s ProNest software for full automation, easy nesting, and material efficiency.